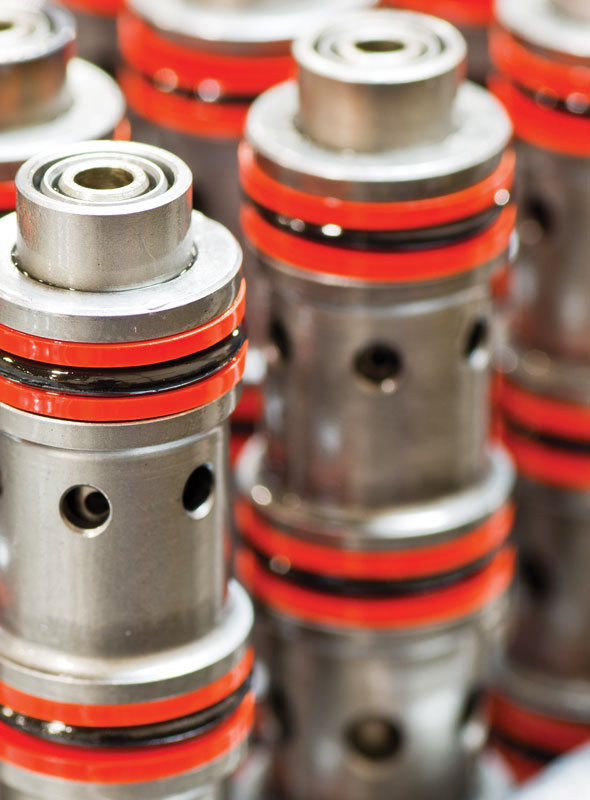

Seals

Innovation in each single item

Our SBS and SEBS-based products guarantee the best solution for any seals: thermal and electrical insulation, UV resistance, a great elastic memory. Our products are fully reusable and freely colorable. They are chemical and external-agent resistant, with a great resistance to atmospheric agents in particular.

Application fields

- Doors

- Windows

- Shower

- Industrial

- Furnishings

- O-Ring

| Product | Hardness | Melt mass flow-rate | Density | Tensile stress | Elongation at break | Tear strenght | Application |

|---|---|---|---|---|---|---|---|

| KEE shA0TH | 20-35 shore A | 2,5-5 g/10min | 0,89-0,92 g/cm3 | 7-9 Mpa | 800-1000% | 20-24 N/mm | Sebs - Great Elastic Return |

| KEE shA0TH | 40-90shore A | 8-10 g/10min | 0,89-0,92 g/cm3 | 8-10 Mpa | 700-900% | 24-30 N/mm | Sebs - Great Elastic Return |

| KPE shA2CL | 65-75 shore A | 17-20 g/10min | 0,99-1,10 g/cm3 | 8-11 Mpa | 700-900% | 25-35 N/mm | Sebs - Standard Material |

| BPE shA2CL | 55-75shore A | 2-6 g/10min | 0,99-1,10 g/cm3 | 4-6 Mpa | 400-600% | 22-26 N/mm | Sbs - Soft Material |

| BPE shD4CL | 40-50 shore D | 15-20 g/10min | 1,10-1,18 g/cm3 | 4-6 Mpa | 600-700% | 60-70 N/mm | Sbs - Hard Material |

| KPE shD4CL | 40-50 shore D | 15-20 g/10min | 1,10-1,18 g/cm3 | 12-14 Mpa | 600-700% | 65-75 N/mm | Sebs - For Rigid Profile |

| DIN 53505 ISO 868 |

DIN 53735 ISO 1133 |

DIN 53479 ISO 1183 |

DIN 53504 ISO 527 |

DIN 53504 ISO 527 |

DIN 53515 ISO 34 |